Infrastructure

- Home

- Infrastructure

Slitting Process

At JK Steel Strips LLP, precision in steel processing goes beyond cutting—it is about consistency, efficiency, and reliability. Our slitting process converts wide master coils into accurately slit, customer-ready coils tailored to exact specifications.

Using advanced slitting technology, we ensure accurate widths, smooth and clean edges, and optimized material utilization with minimal wastage for a wide range of applications.

Shearing / Sheet Processing

Our shearing and cut-to-length process transforms steel coils into flat, uniform sheets ready for immediate use. The process is engineered to maintain dimensional accuracy and superior surface quality.

Coils are uncoiled and leveled for flatness, cut to exact lengths using high-speed shears, and stacked for dispatch—making this process ideal for automotive, fabrication, appliance, and construction industries.

Packaging

At JK Steel Strips LLP, packaging is treated as a critical extension of our manufacturing process. Each coil and sheet is packed to ensure protection against moisture, handling damage, and transit wear.

We use industry-standard wrapping, edge protectors, and secure strapping to maintain surface quality and dimensional integrity until final delivery. Customized packing solutions are also offered based on customer requirements.

Testing & Quality Inspection

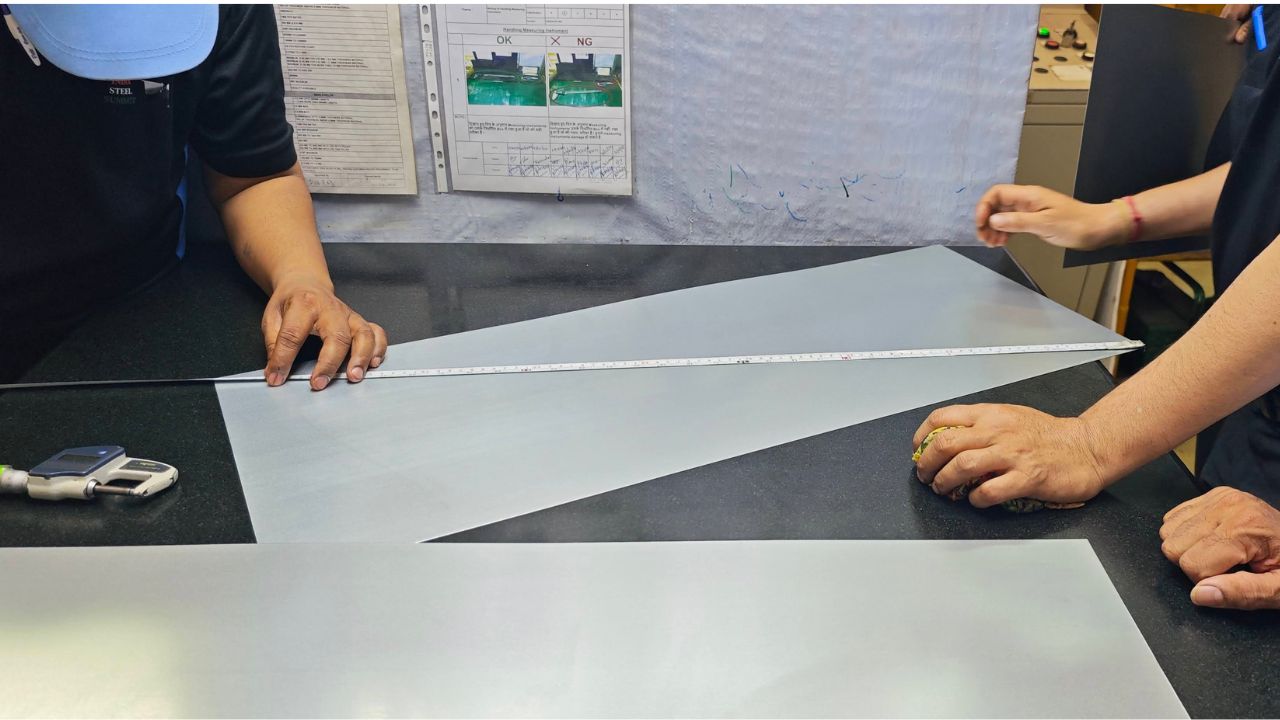

Quality assurance at JK Steel Strips LLP is an integral part of our processing workflow. Each batch undergoes systematic inspection to ensure compliance with dimensional and surface quality standards.

A dedicated flatness inspection table is used to verify sheet uniformity, straightness, and edge alignment. Visual inspection is carried out to detect surface defects such as waviness, camber, and handling marks.

Thickness verification, width checks, and coil edge condition assessment are performed using calibrated measuring instruments, ensuring that only quality-approved material is cleared for packing and dispatch.