Aluzinc Steel

- Products

- Aluzinc Steel

Aluzinc Steel

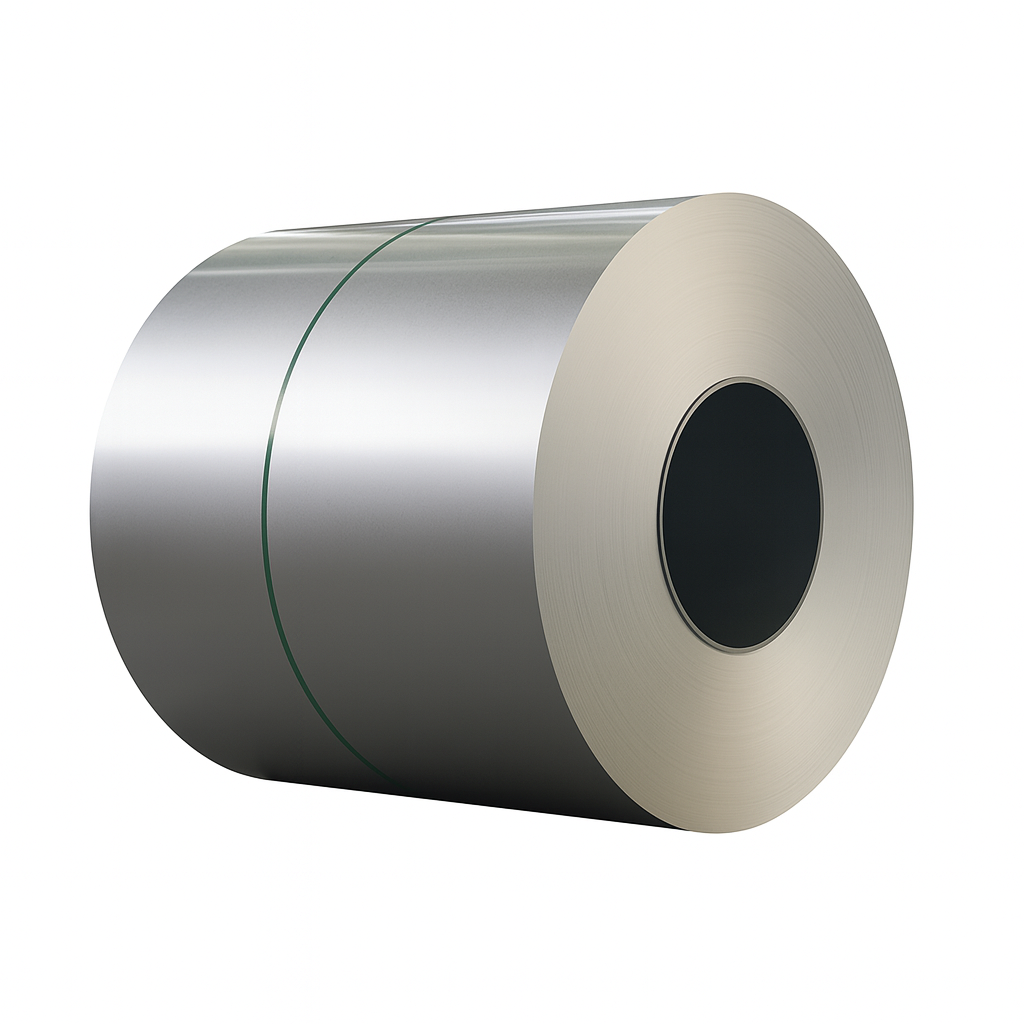

We are widely recognized for supplying premium-quality Aluzinc Steel, a high-performance material engineered for superior durability and long-term corrosion protection. Produced through the Hot-Dip Aluminium-Zinc coating process, it features an Aluminium-Zinc-Silicon alloy coating for exceptional corrosion resistance, high reflectivity, and uniform finish.

Types of Aluzinc Steel

Type 1 – 55% Aluminium, 45% Zinc

High corrosion resistance and heat reflection. Ideal for harsh environments.

Type 2 – 45% Aluminium, 55% Zinc

Slightly lower heat & corrosion resistance than Type 1, economical, still superior to galvanized steel.

Type Comparison

| Type | Composition | Advantages | Cost |

|---|---|---|---|

| Type 1 | 55% Alu / 45% Zinc | Excellent corrosion & heat resistance | Higher |

| Type 2 | 45% Alu / 55% Zinc | Good performance, superior to GI | Lower |

Available Range

| Thickness | 0.25 – 3.00 mm |

|---|---|

| Width | Up to 1500 mm |

| Coating Weight | 70 – 280 GSM |

| Most Preferred Grade | AZ150 |

Size Chart

| Thickness (mm) | Width (mm) | Coating (GSM) | Grade |

|---|---|---|---|

| 0.25 – 0.50 | 600 – 1250 | 70 – 150 | CS / D / DX51D |

| 0.50 – 1.20 | 900 – 1500 | 90 – 180 | DX53D / DX54D |

| 1.20 – 3.00 | 1000 – 1500 | 120 – 280 | DD / EDD / DX56D |

Key Features

- Consistent chemical composition

- Excellent surface finish

- Long service life

Technical Properties

- Corrosion & Heat Resistance: Up to 6× better than zinc-coated steel; excellent edge protection; high reflectivity

- Weldability: Similar to galvanized steel, requires correct settings

- Formability: Can be rolled, bent, or deep-drawn; depends on base metal grade

- Surface Finish Options: Skin-passed, Regular Spangle (on request)

Applications

- Roofing & construction

- HVAC systems

- Automotive components

- Electrical enclosures

- Appliances & industrial panels